October 8th, 2021

Man Versus Machine

Dragging dead weight from one spot to another is about the hardest work you could ask your body to do. It’s autumn, so I’m assuming the deer hunters out there know what I’m talking about. So it’s no wonder that somebody long ago, in a distant land, invented ... the wheel, introducing machine automation to humanity. Since the dawn of time, mankind has been automating—finding ways to make simple tasks easier and ways to get more output with less input. While the wheel might be one of the earliest examples of this, in its fullest form, the modern utility company might be one of the greatest examples of the benefits of automation.

The 8th Wonder of the World

The electric utility should probably be considered the 8th wonder of the world. The electric utility has enabled mankind to achieve unbelievable things in the last century—computers, the Internet, person to person communication, etc. In contrast, if the lights go out, the consequences would be disastrous. Ted Koppel, in his book, Lights Out: A Cyberattack, A Nation Unprepared, Surviving the Aftermath, proclaimed, “The only institution with real power to decide how the power industry is protected is the power industry.” He later went on to say, “There’s plenty of people that understand what needs to be done. It’s policy and it’s money standing in the way.” What he meant was that utility companies are responsible for inspecting their system and buying down risk by making repairs, capital improvements, and other systematic hardening of their system’s reliability, safety, the dollars allocated for inspection is not where it needs to be.

The Conundrum

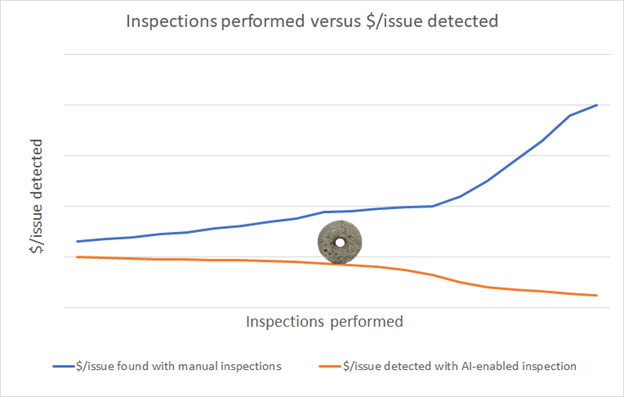

The conundrum is: Do you want more information on the condition of your system? Well, you need more inspections. Do you want more inspections? Well, you need to spend more money. Do you want to spend more money? Well, no.

Machine Automation

So, we’re back to automation. For all of the automation and technology needed to generate and deliver electricity, the methods of maintaining the grid are surprisingly manual. Just the effort of inspecting to find issues and weaknesses (helicopter flights, ground crew inspections, manual engineering reviews, work order generation and prioritization, and eventual dispatch) is really manual, expensive, and dangerous; line inspectors today generally inspect using the same methods they did in the early 20th century. To put a cherry on top, nothing about the rate treatment for that inspection process incentivizes additional spending for the multitude of manual steps needed to get quality information. Do you want more operations and maintenance (O&M) dollars? No! This demands a true step-change in technology.

An “Invent the wheel moment” is needed so utilities can perform more inspections, more accurately, and prioritize work more optimally; all at less cost. Is that even possible?? The answer is YES!—by incorporating AI-enabled analysis into the inspection program. The technology is available; now companies just need to get the ball rolling.

Case Study

A recent Unmanned Aerial Vehicle (UAV) inspection was performed on a double circuit 345kV transmission line, and once the imagery and point cloud were generated in raw form, the AI algorithms were able to produce key inspection findings in approximately ten minutes. That’s lightning fast! Contrast this with the standard manual processes (involving expensive helicopter rentals, weeks of time, hundreds of man hours in the field and back office review), which can take months or years and often produce suboptimal Work Order assignment results. Those manual processes cannot scale - more inspections result in more cost. Get the ball rolling on an inspection program built on machine learning, and the cost per issue found actually reduces, as shown in the figure above.

Remarkable Impact

Recent field studies show the ultimate benefit of the of the AI-enabled inspection program—its scalability can remarkably give utilities the “special power” of performing more inspections, more accurately, and prioritize work more optimally; all at less cost. We are working with utilities that are incorporating machine learning into their inspection programs. Click the link below to learn more about how to get your ball rolling.

Jason Buettner, CobraVision

(IMAGE SOURCE: http://rhizome.coop/taking-decisions-defining-consensus/challenges-facing-transformation-too-busy-wheel/)

Who wins? Mongoose vs Cobra

Take The Cobra Challenge

You choose:

- Windmill

- Transmission Tower

Just pick your type of challenge and prepare to simulate real life using LEGOs. You build, then we evaluate using AI. Simply sign-up and we'll send everything you need.

Schedule An Introductory Call

Get a quick, high-level snapshot of how AI from CobraVision achieves a higher level of predictability for safety, compliance and restoration.

Schedule a Meeting